165 Ton Betenbender Model 10'-160, 10' Overall, 102.5" Between Housings, Made in America

Open Height: 14"

Closed Height: 6"

Throat Depth: 8"

IPM (Press): 31 Inches Per Minute

IPM (Rapid Approach): 68 Inches Per Minute

IPM (Return): 86 Inches Per Minute

HP: 20

54 Amps @ 208.230; 27 Amps @ 460

STANDARD FEATURES

3 Speed Ram

All Hydraulic Fluids Included

All Steel Construction

American Made Hoses and Fittings

American Made Valves and Motors

Bottom Time Delay

Clamp Type Backgauge- Manual Adjustable X, Y, & Z - 24”

Cylinders are Steel, Double Acting Piston Type with Hardened, Ground and Chromed Rods

Depth Stop with Digital Readout

Disconnect Switch

Front & Back of Bed Machined Smooth for Mounting of Gauges

Hardened Pins with Spherical Bearings for Alignment

Hour Meter

Hydraulic Pressure: 2500 psi

NEMA Electrics

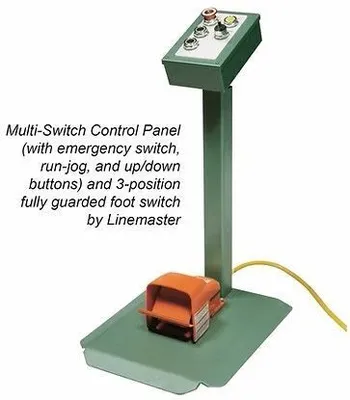

Three Position Foot Switch by Linemaster

OPTIONAL FEATURES

24” Support Arms “Slide” Type

Keylock Switch

Light Curtain

Manual Front Reading Backgauge (24”) with Mechanical Readout

One Shot Lubrication

Operator Station Palm Control

Variable Tonnage Control

Work Light

208v Single Phase

Additional Foot Pedal with Keylock

Air Lift (Recommended for 4/Way Dies)

Angle Brackets (Plates) for Bottom

Angle Brackets (Plates) for Top

Automatic Lubrication

Bed Machining Angle Brackets

Bolt/Shim Kit for Leveling

CNC Backgauge

CNC Ram Stop

Die Holder/Riser

Die Rollover Bars (Recommended for 4/Way Dies)

Disappearing Stops

Dove Tails

Dual Calibration

Extended Support Arms (each)

Extra Length on Backgauge

Increase Stroke Length

Increase Throat Gap or Increase Open Height

Micrometer Precision Gauge Unit (2 Required)

Oil Cooler

Palm Buttons/Foot Control System (Hand buttons to preset height, stop and hold, foot to continue to shut height)

Power Front Reading Backgauge with 5 Station NC “GO-TO” Positioner on Pendant

Power Ram Adjustment with 5 Station NC “GO-TO” Positioner on Pendant

Ram Machining

Special Application Tooling

Special Paint Colors

T-Slots

We use cookies to improve your experience. Privacy Policy.